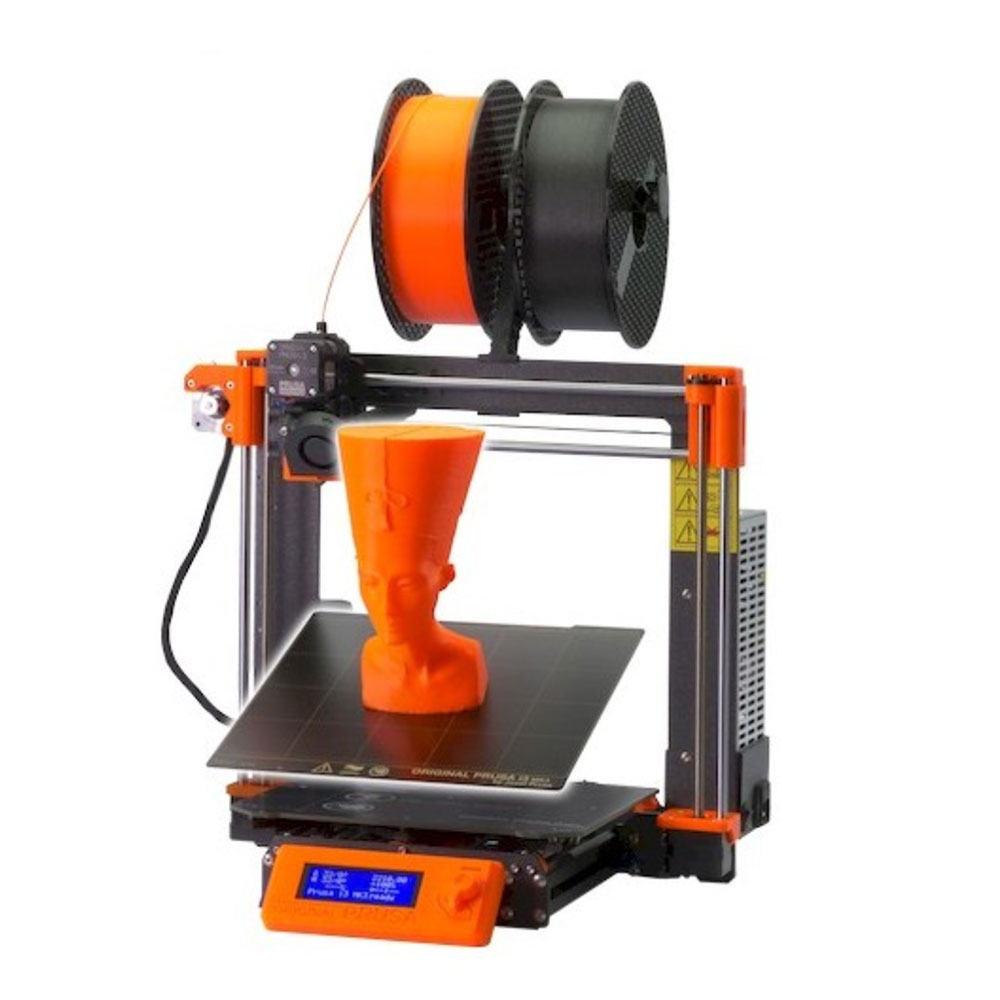

Recover Shifted Layers: The new EINSY RAMBo motherboard with Trinamic drivers not only makes the MK3 silent but it also can detect skipped steps and layer shifting. We can also detect stuck filament and offer the user to clean the nozzle. The MK3 can recognize running out of the filament, pause the print and ask the user to insert a new spool. After restoring the power, you can continue with printing.įilament Sensor: Our optical filament encoder detects the presence of a filament and also its movement. It detects power interruption and shuts down the heatbed and extruder heating. Power Panic: Did you ever tripped over the extension cord and lost a 20-hours print? MK3 will save you! The printer can fully recover from the loss of power. In normal mode, we have also increased the printing speed. But also in normal mode is the printer quieter than 99 % of the available printers. Silent & Faster Printing: Thanks to the new Trinamic2130 drivers and Noctua fan, MK3 is extremely quiet in the stealth mode. The frame is also optimized to add 10 mm of Z height totaling at 210 mm. It provides the same rigidity as some other printers while providing the sleek look of our milled Dural frame. You can choose between two types of sheets - smooth PEI sheet (default option, already available) and textured powder coated PEI (this will be available later).įrame Stability: With the MK3 we are introducing the reworked Y axis from aluminum extrusion. Removable Heatbed: The new MK52 Magnetic HeatBed holds replaceable alloy spring steel sheet with PEI surface. MK2S also became The Best 3D Printer for 2018 in "Workhorse" category on Guide with score of 9.3 (the highest rated printer overall).Īnd the new MK3 is even better! With its rebuilt extruder, a plethora of sensors and the new magnetic MK52 heatbed with replaceable PEI spring steel print sheet, it's our best 3D printer yet! Our previous model is the winner of the 3D Printer Shootout 20 in the prestigious MAKE: Magazine and for more than a year, it's the best desktop 3D printer according to Trends. I've got an E3D 0.35mm plated copper on order.The Original Prusa I3 MK3 is the successor to the award-winning Original Prusa i3 MK2/S 3D printer. Cheaper nozzles may not be as accurate and might have other quality issues. They do produce a 0.15mm but it's sold as experimental. Also keep in mind that details on vertical walls will depend more on layer height.įWIW: I believe the smallest supported noze from E3D is 0.25mm. Printing that part with a 0.20mm or 0.15mm nozzle would take longer and not gain more detail in this case.

However, the bolts also printed nicely with a 0.30mm nozzle, and more quickly.

Using a 0.25mm nozzle, the bolts were clearly printed. Using a 0.40mm nozzle, there was just a smear at that location. For example, I printed 1:100 miniatures with bolts on the top surface. A smaller nozzle makes sense if you need to print details on your XY plane smaller than your existing nozzle. I have tried using a 0.20mm with no luck, but have since gained a lot of experience working with a 0.25mm nozzle. Use the highest quality filament that you can find. My biggest fear would be nozzle clogging with such a tiny hole size. The 20 DP gears in my clock are half the diameter of the gears in a wooden clock.Ī 0.2mm nozzle should be capable of printing smaller gears. As a reference, I make 10 DP gears on a CNC router with a 1/8" router bit. I made the large gears 0.2" thick and the pinions 0.35". They are easy to print and appear to be fairly strong. 20 DP appeared to be a great size and that is what I used in my clock. I tried 16, 20, 24, and 30 DP sizes in addition to the 36 DP from the hummingbird. I started with an experiment to find out the best size. My next gear project was a pendulum clock with 20 DP gears. It is functional, but slightly pushing the capabilities of the standard nozzle. This would make a 36 tooth gear around 1 inch in diameter. The gear teeth in that design are extremely small, somewhere around 36 dot pitch.

The first item was a mechanical hummingbird downloaded from Instructables. I have printed a few gears with my MK3 using the default 0.4mm nozzle.

0 kommentar(er)

0 kommentar(er)